How To Use Industrial Displays In a Wide Temperature Environ

Industrial Touch Displays have extremely high requirements for their performance due to harsh environments such as high and low temperature, dusty, watery, and oily applications in the industry. Especially in the high and low temperature environment, it is a great challenge to industrial display products. Then, the high and wide temperature performance of industrial displays is very necessary.

Next, follow the industrial display suppliers to explore: How does industrial display achieve wide temperature use? How does temperature change affect industrial displays with different touch methods?

1. Wide temperature mode and working principle

1) Method 1: Using low temperature heating method

Low-temperature heating has two methods: point-by-point heating and whole-surface heating. The overall power consumption of such a display will increase 4-6 times. For example, the power consumption of a 15-inch LCD monitor at normal temperature (22°C) is 20ww, and the power consumption in a low temperature environment (-40°C) is 90-120w. This heating method makes the machine in the process of long-term use, Sometimes the liquid crystal will flow out or it will be difficult to restore.

2) Method 2: Increase the brightness of the LCD screen

By developing a special high-voltage bar (which can generate a starting voltage of 2000v-3000v), the backlight tube is turned on in a low temperature environment (-40°C), and the liquid crystal heats up due to the huge heat generated by the backlight tube. It solves the problem of low temperature working of liquid crystal, and also solves the problem of visibility under the sun. This method is referred to as the brightening method.

Disadvantages of the first and second methods: ① Both of these two methods add a lot of accessories and reduce the reliability. ②It is more troublesome to assemble and produce, it is easy to cause defective products, and the defective product rate is higher. ③The device's ability to resist shock and vibration is reduced. ④In the aging test, it is found that the aging speed is extremely fast under the environment of 50℃, and the acceleration rises, especially the brightening method, the life is only 1/10 of the normal.

3) Method 3: New LCD high and low temperature application technology, the product can work normally at low temperature without heating or brightening

The basic principle is as follows: the liquid crystal does not freeze or undergo a state transition at low temperatures, otherwise neither the heating method nor the brightness enhancement method can work, so we thought of using software to correct the drift of its electrical characteristics. Try to trigger the work of the liquid crystal at low temperatures. This requires adjusting the driving timing of the liquid crystal and so on. Through a large number of experimental studies and extensive applications, this technology has been very mature. No matter how the ambient temperature changes, the normal operation of the liquid crystal can be ensured by widening the trigger sequence and matching the corresponding drive.

2.the impact of wide temperature on different touch screens

1) Capacitive screen

The working principle of a Capacitive Touch Screen is to use a touch sensor to induce a voltage on the conductor on the screen, thereby generating a relative current, and measuring the touch point by distance. In the case of low temperature, the skin surface of the hands has low moisture content, and the dry and cold skin has poor conductivity. At the same time, when the ambient temperature is low, the performance of the sensor will also be affected, and the industrial touch display cannot recognize the touch position well, causing the touch screen to malfunction. The operating temperature of the touch screen is usually between -5°C and +60°C, especially in winter, the northern area is more affected.

2) Resistive touch screen

The resistive touch screen is less affected. On the one hand, because of the different processes used, the micro-circuit on the touch screen is connected to work, which is weakly affected by the temperature. On the other hand, the technological level of the resistive screen is relatively mature, and the materials used are all able to withstand the test and continue to be used. The temperature of the resistive screen is required to be between -20℃~65℃, which can meet most of the use environments.

3) Infrared touch screen

The accuracy of the infrared touch screen is completely free from current, voltage and static electricity interference, and is suitable for various environmental conditions with light pollution. However, the infrared touch screen is limited because of its single sensor, easy to be damaged and aging, and the touch interface cannot withstand pollution, destructiveness, and complicated maintenance. When the temperature is extremely low, the static electricity generated during the use of industrial displays tends to attract dust, thereby affecting the use. Suitable for use in the aerospace field.

4) Surface acoustic wave screen

It shows that the sonic touch screen has extremely high definition, the light transmittance can reach 92%, the anti-scratch, abrasion performance is also the best, the response is sensitive, and the accuracy is completely unaffected by environmental factors such as temperature and humidity. In contrast, the cost of construction and maintenance are also high. Surface acoustic wave screens need frequent maintenance. If dust, oil stains or even liquids are contaminated on the surface of the touch screen, the wave guide groove on the surface of the touch screen will be blocked, causing the sound wave to not be emitted normally or causing the waveform to change and the controller cannot recognize it correctly. Therefore, strict attention must be paid to environmental hygiene, and the surface of the touch screen must be wiped frequently to keep it smooth and clean, and a complete and thorough erasure must be performed regularly. If the surface of the sonic screen is condensed or oily in winter, it will be quite troublesome to clean.

3. Industrial-grade display that meets wide temperature requirements

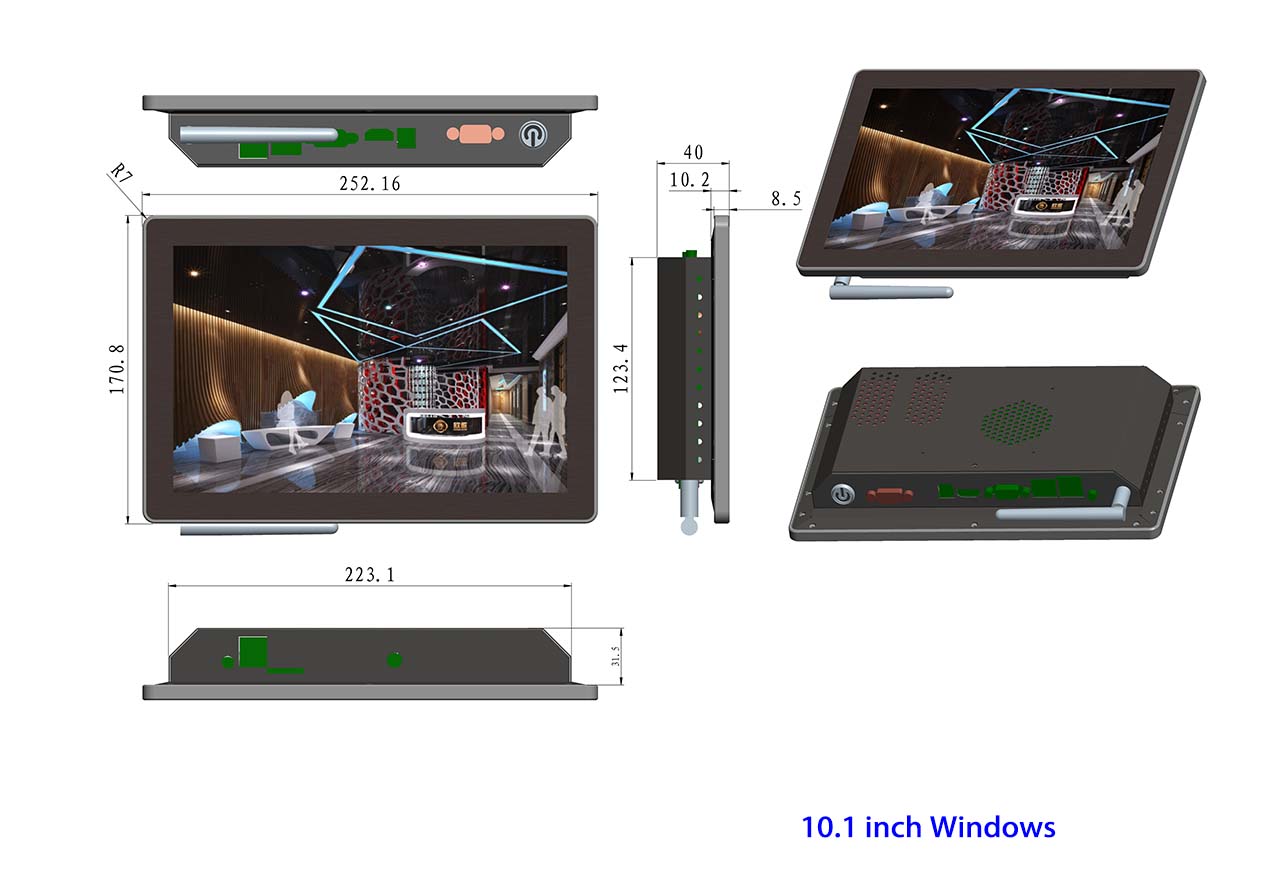

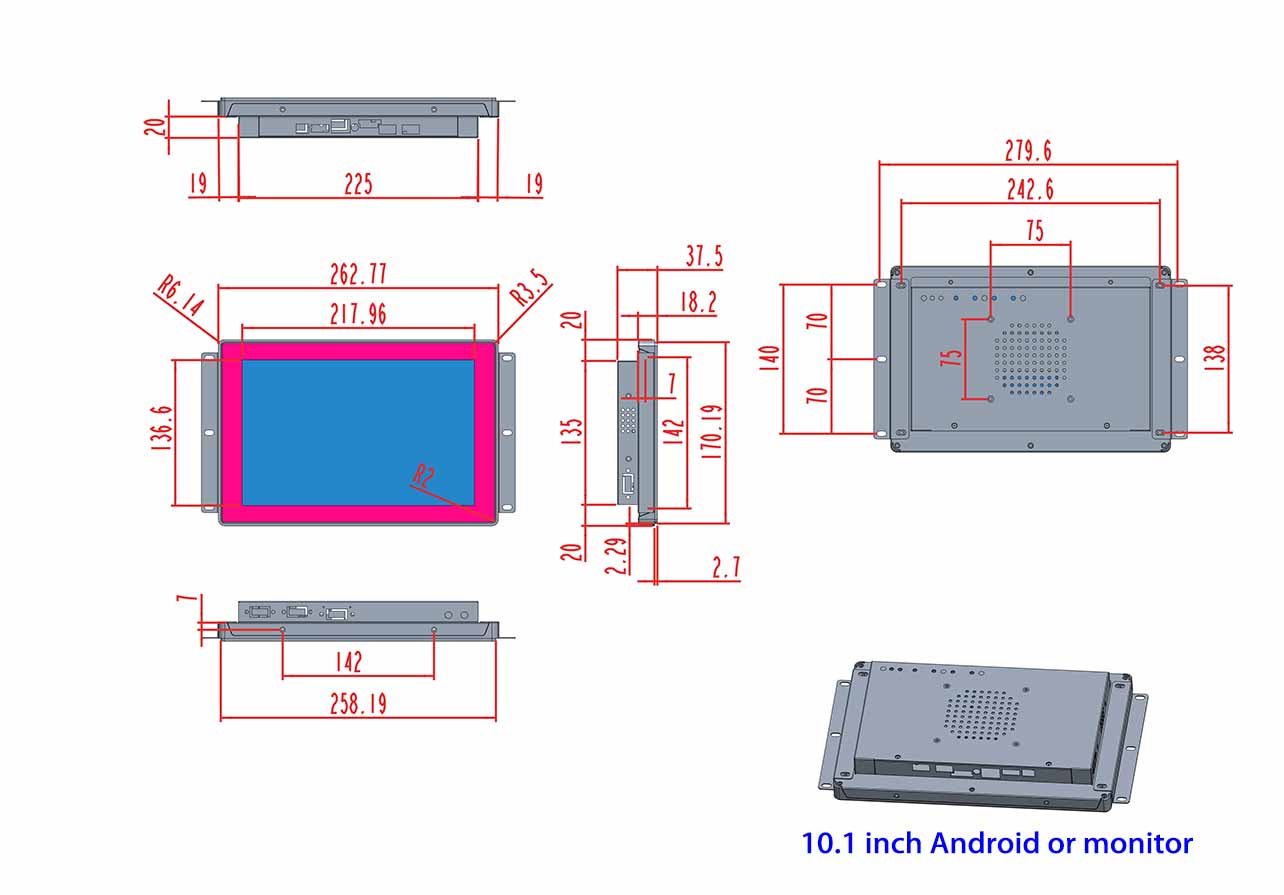

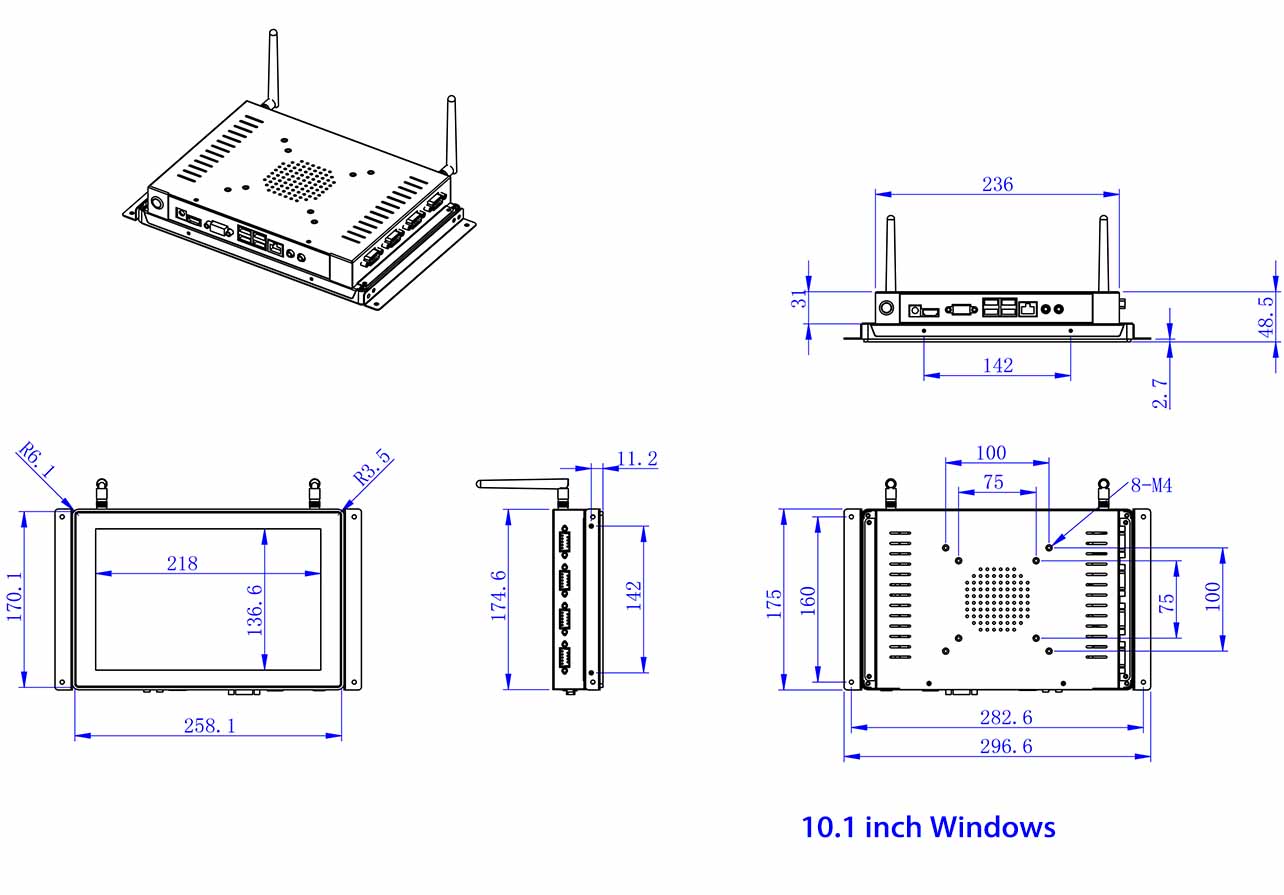

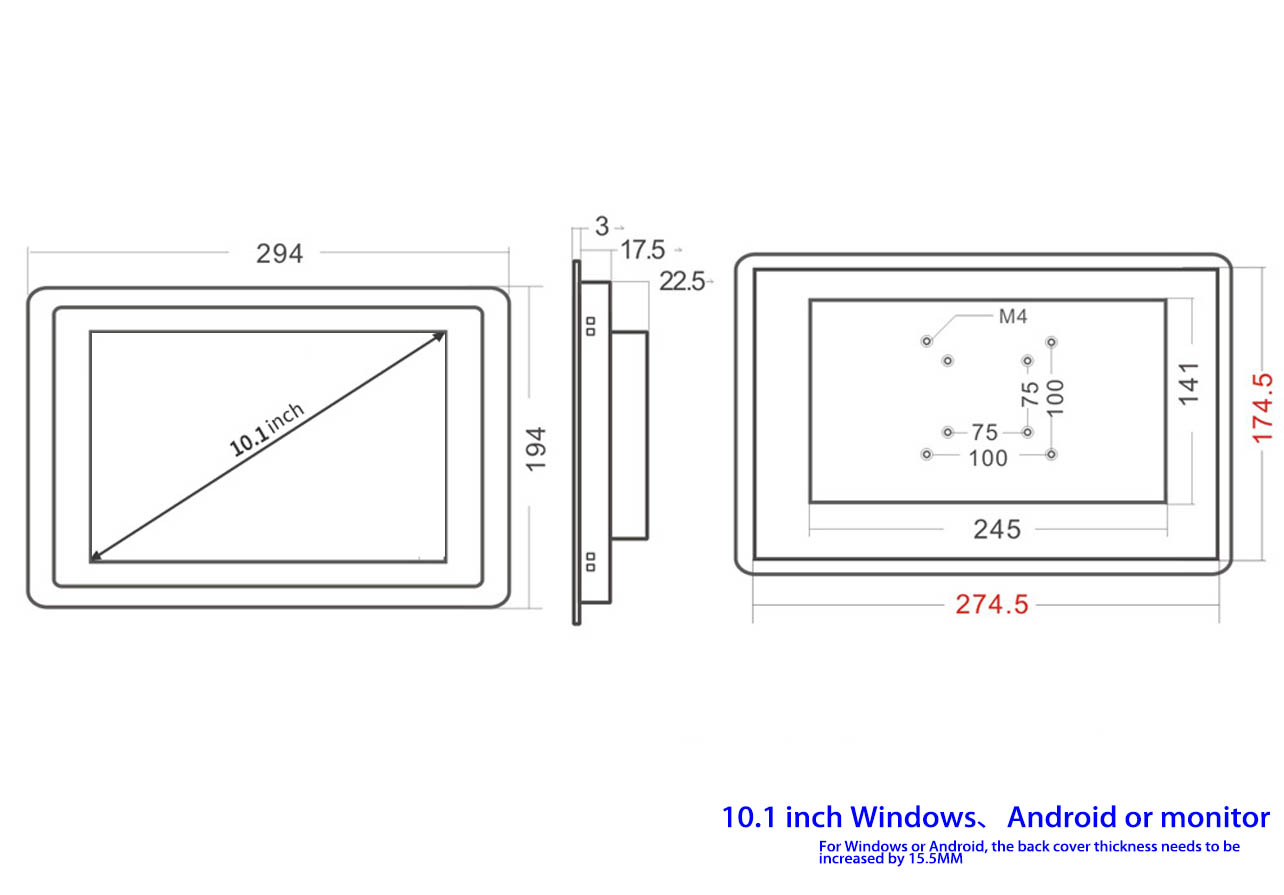

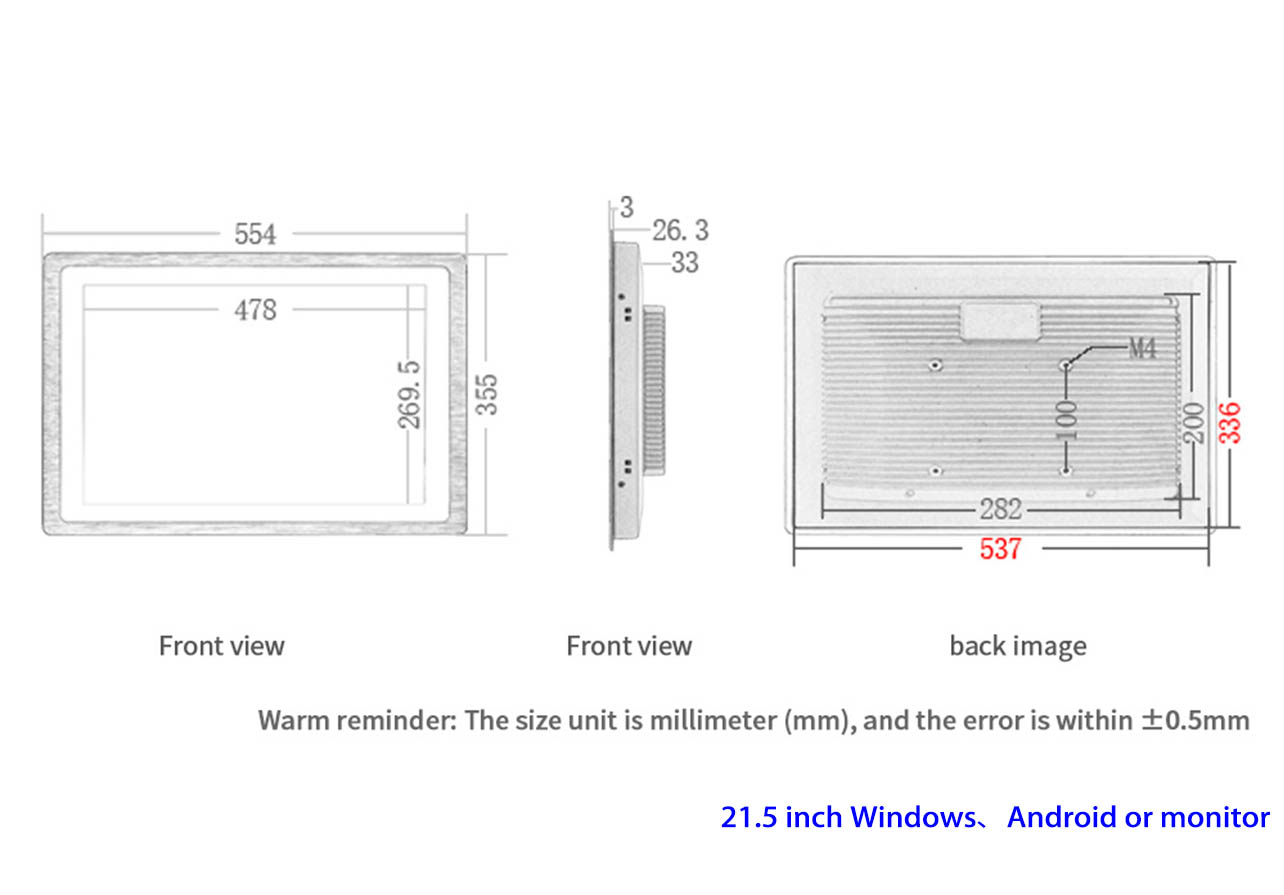

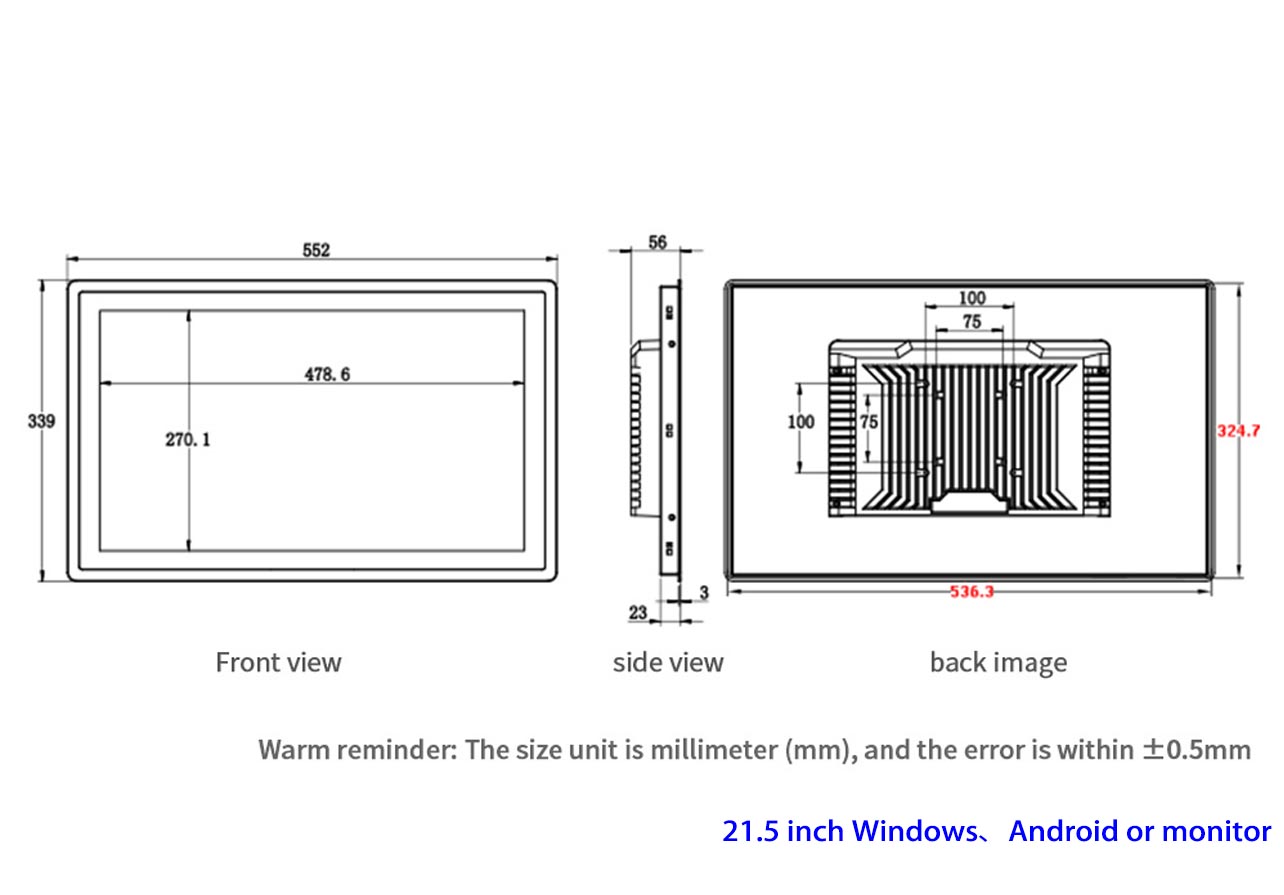

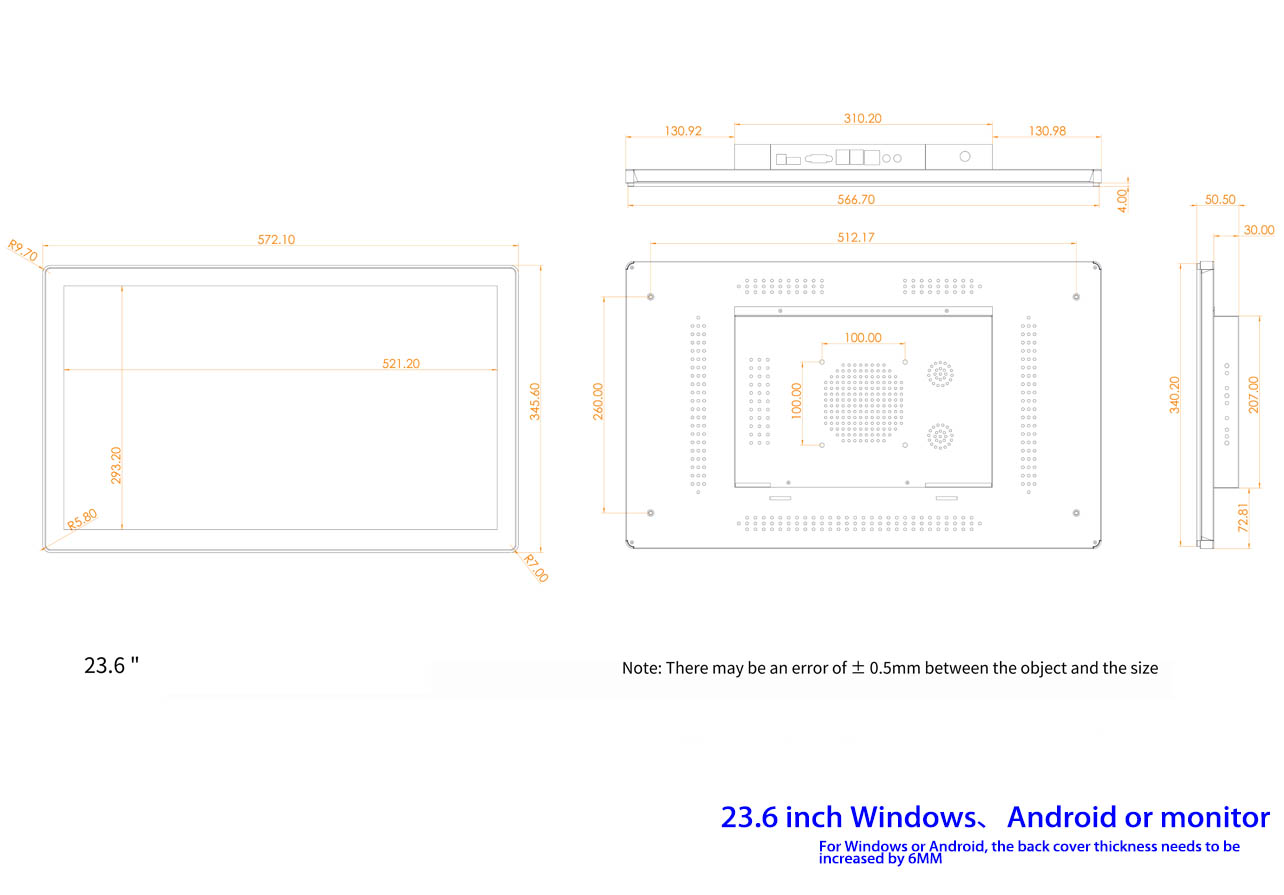

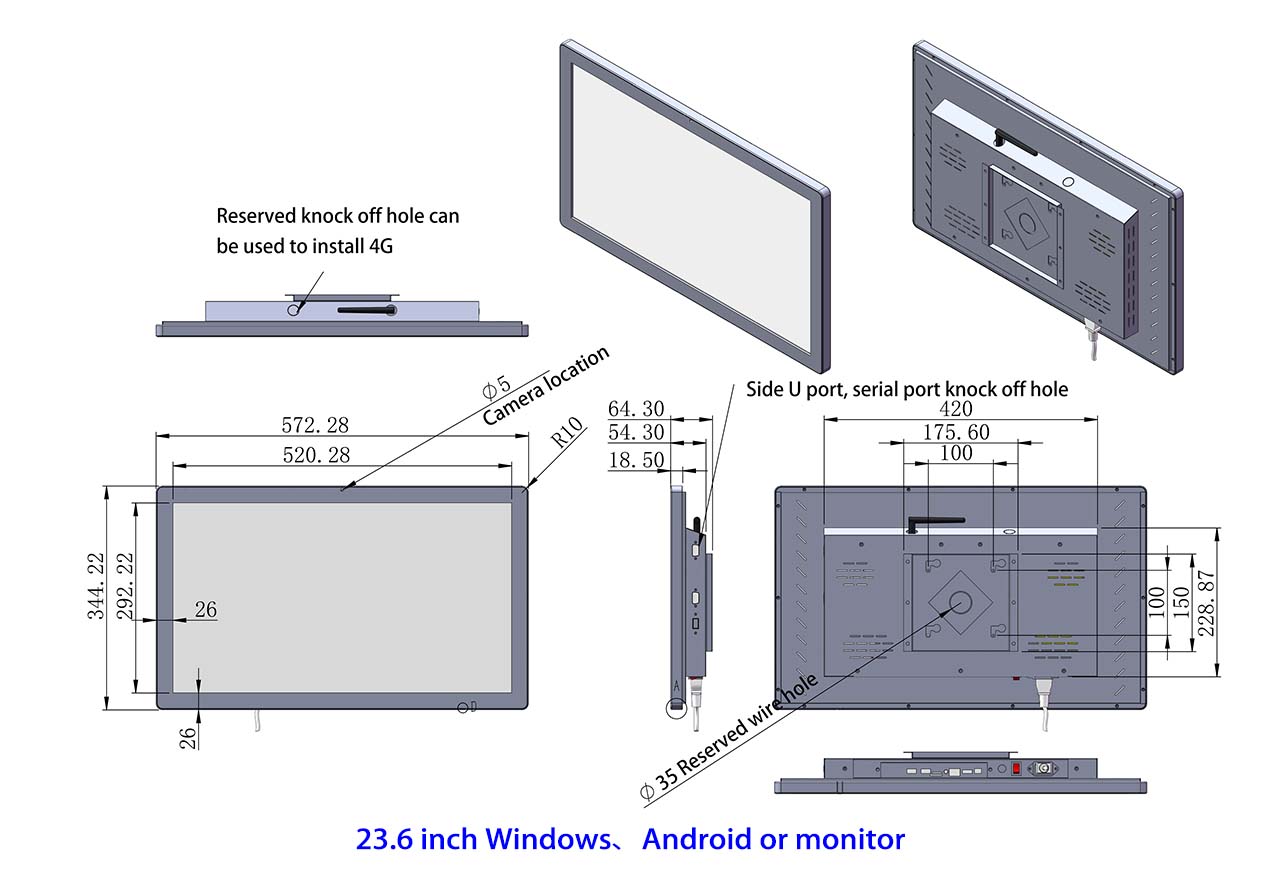

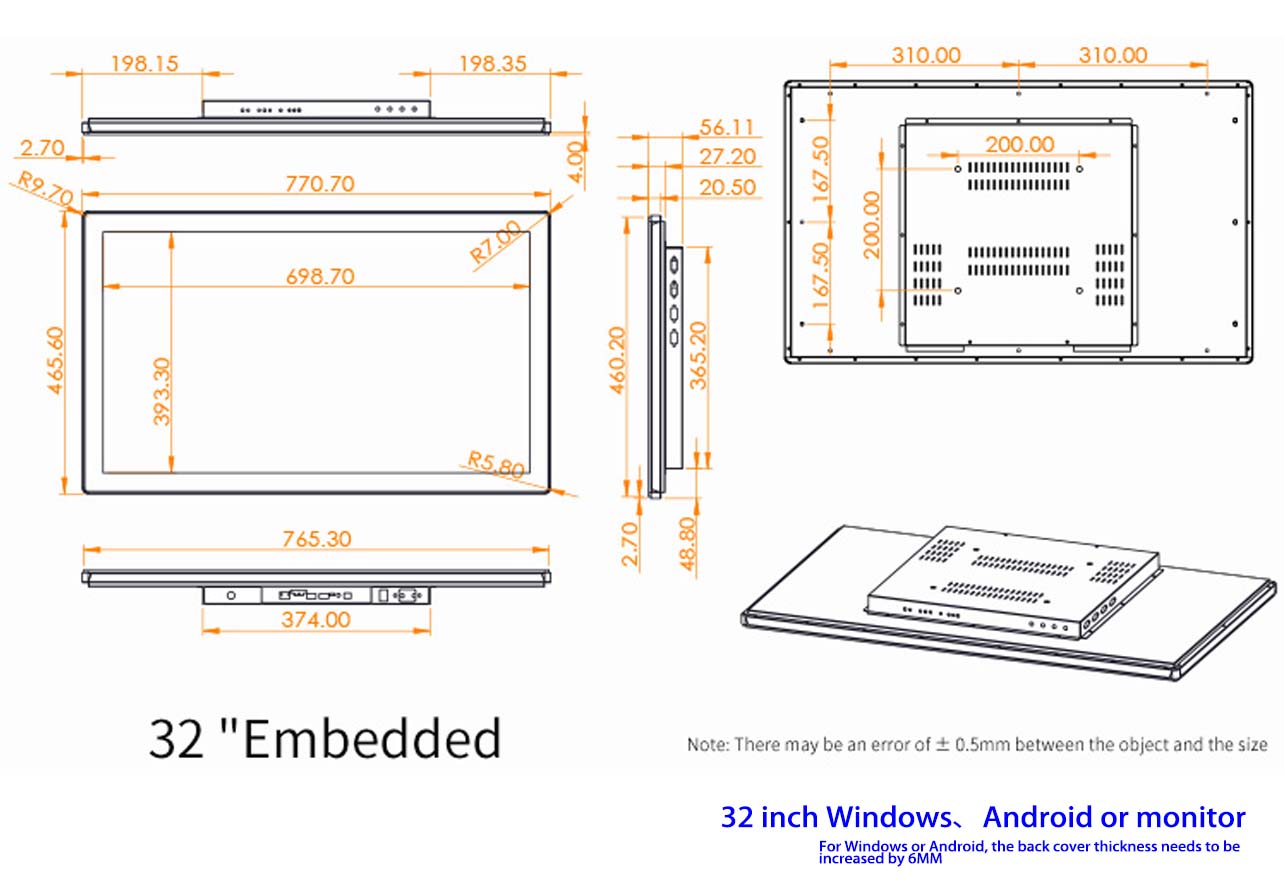

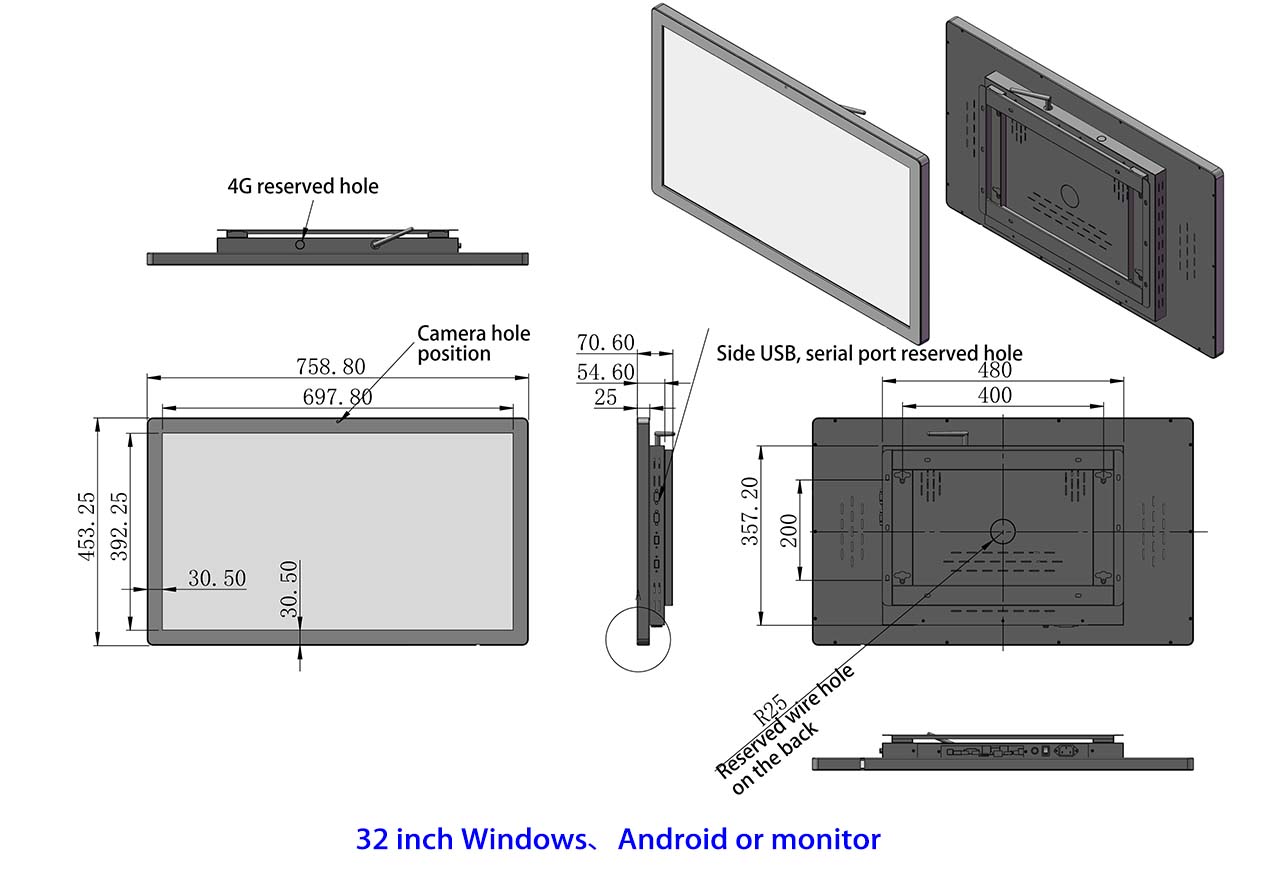

The front panel is designed with aluminum wire drawing process, and the arc edge is harmonious; at the same time, the touch mode supports five-wire resistive and capacitive, with a wide temperature LED backlight LCD screen. The wide temperature performance of the whole machine has been tested by long-term controllable high and low temperature standards. . In addition, it pays more attention to its reliability, environmental adaptability, real-time, scalability, EMC compatibility and other performances in the materials of the complete machine.

In terms of configuration, the self-developed RJ45 driver board is used to support HDMI input, DVI input, VGA input interface and other anti-dropping DC thread wide-voltage power supply interfaces, which can meet the needs of the scene. At the same time, it also supports buckle embedded, horizontal shutter, wall-mounted, desktop and other installation methods to unlock more application scenarios.

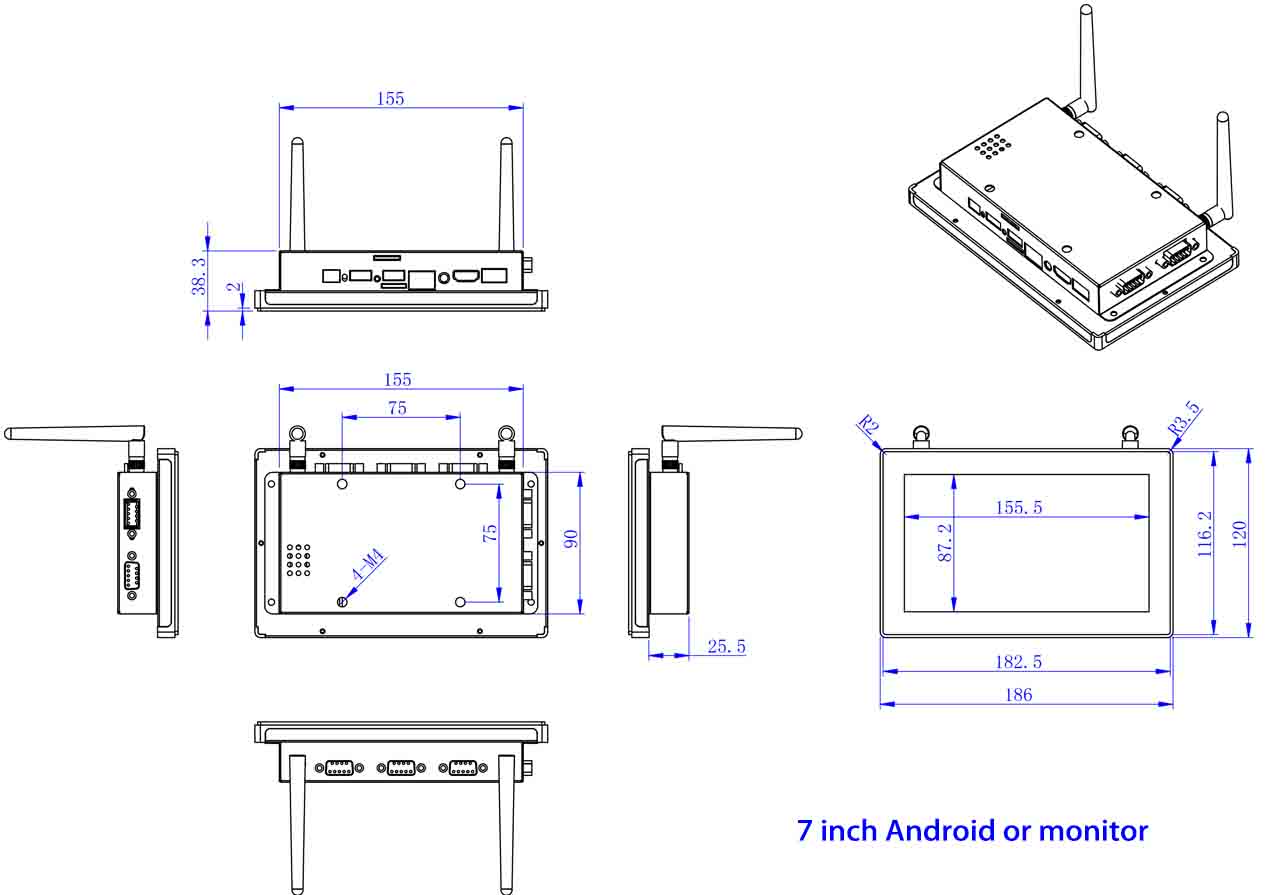

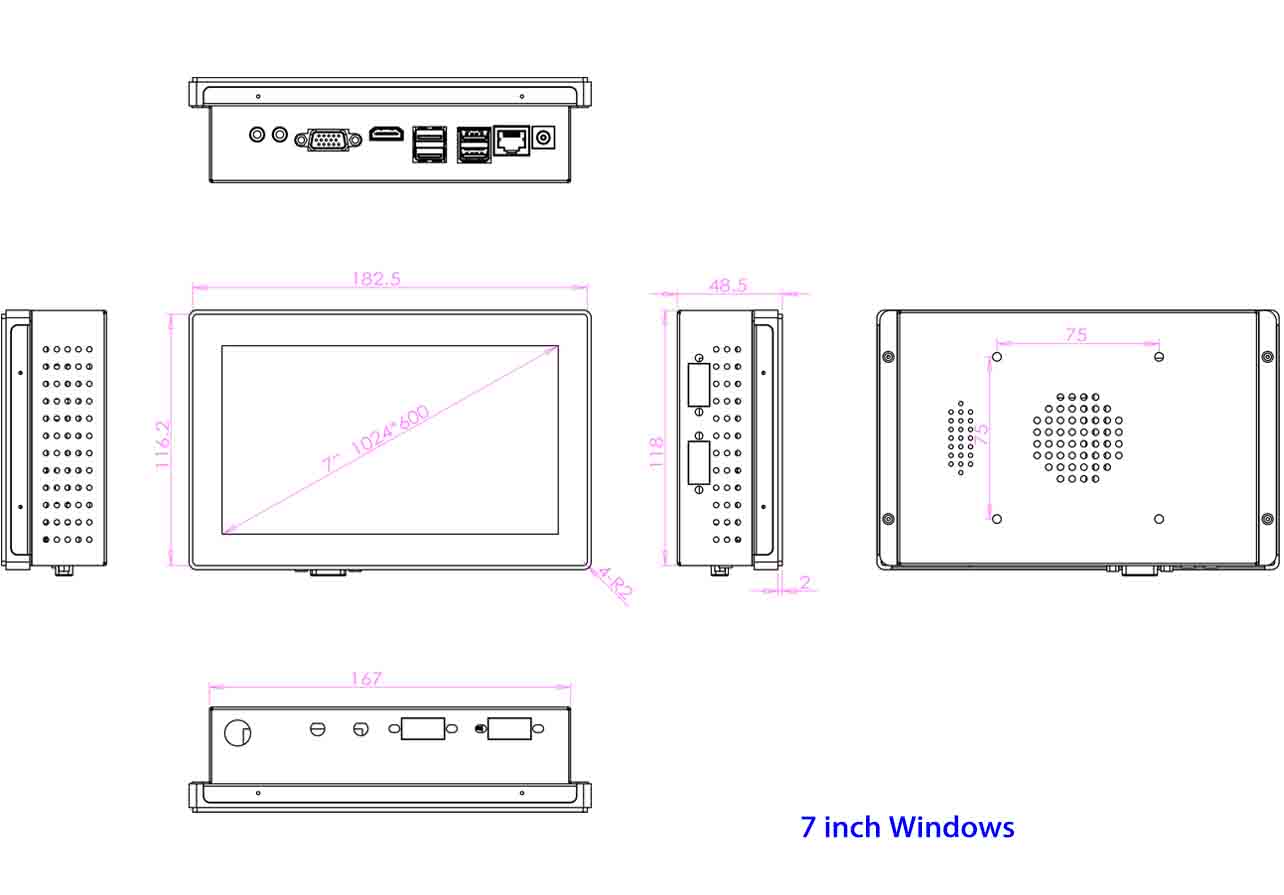

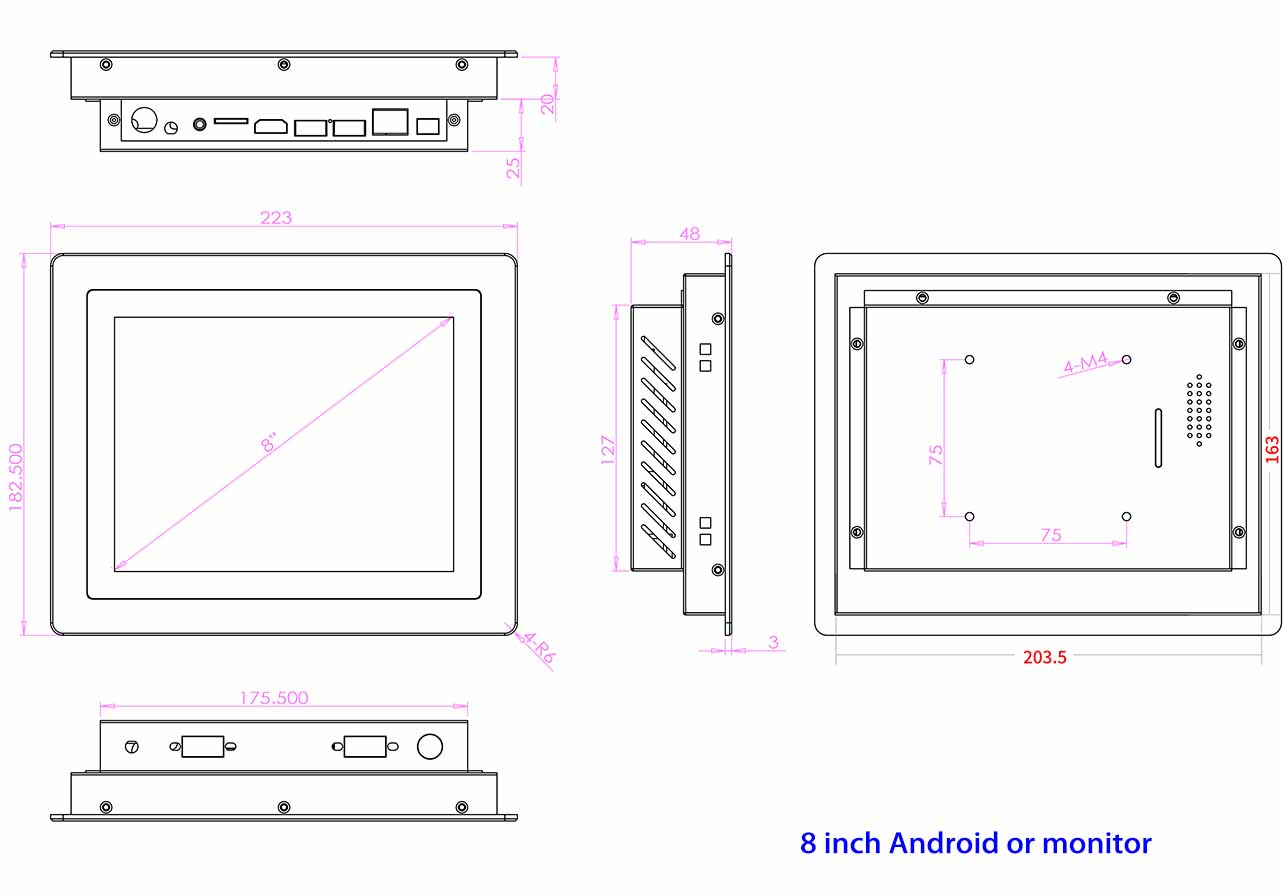

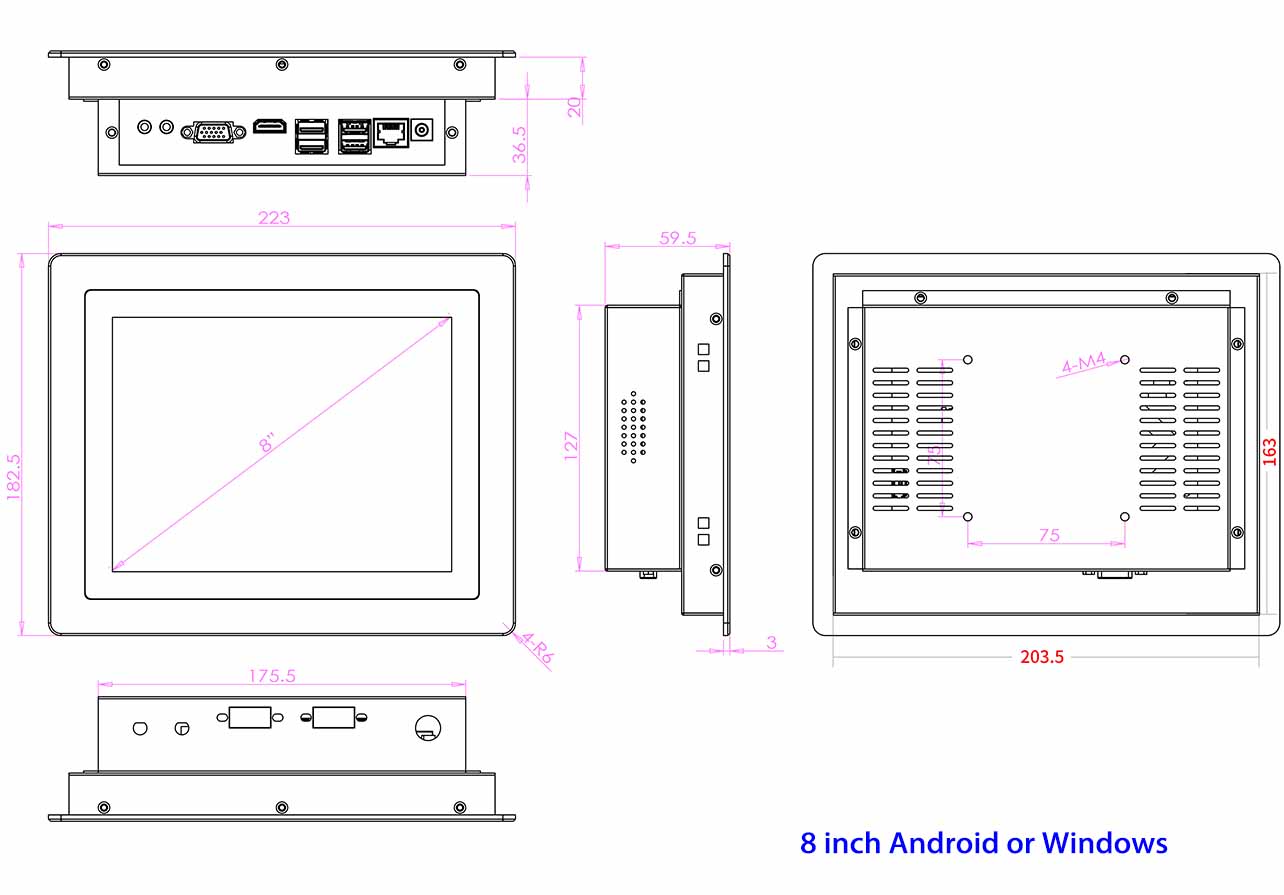

The company also provides Industrial Tablet Computers and mini computers, please feel free to contact us if necessary

Next, follow the industrial display suppliers to explore: How does industrial display achieve wide temperature use? How does temperature change affect industrial displays with different touch methods?

1. Wide temperature mode and working principle

1) Method 1: Using low temperature heating method

Low-temperature heating has two methods: point-by-point heating and whole-surface heating. The overall power consumption of such a display will increase 4-6 times. For example, the power consumption of a 15-inch LCD monitor at normal temperature (22°C) is 20ww, and the power consumption in a low temperature environment (-40°C) is 90-120w. This heating method makes the machine in the process of long-term use, Sometimes the liquid crystal will flow out or it will be difficult to restore.

2) Method 2: Increase the brightness of the LCD screen

By developing a special high-voltage bar (which can generate a starting voltage of 2000v-3000v), the backlight tube is turned on in a low temperature environment (-40°C), and the liquid crystal heats up due to the huge heat generated by the backlight tube. It solves the problem of low temperature working of liquid crystal, and also solves the problem of visibility under the sun. This method is referred to as the brightening method.

Disadvantages of the first and second methods: ① Both of these two methods add a lot of accessories and reduce the reliability. ②It is more troublesome to assemble and produce, it is easy to cause defective products, and the defective product rate is higher. ③The device's ability to resist shock and vibration is reduced. ④In the aging test, it is found that the aging speed is extremely fast under the environment of 50℃, and the acceleration rises, especially the brightening method, the life is only 1/10 of the normal.

3) Method 3: New LCD high and low temperature application technology, the product can work normally at low temperature without heating or brightening

The basic principle is as follows: the liquid crystal does not freeze or undergo a state transition at low temperatures, otherwise neither the heating method nor the brightness enhancement method can work, so we thought of using software to correct the drift of its electrical characteristics. Try to trigger the work of the liquid crystal at low temperatures. This requires adjusting the driving timing of the liquid crystal and so on. Through a large number of experimental studies and extensive applications, this technology has been very mature. No matter how the ambient temperature changes, the normal operation of the liquid crystal can be ensured by widening the trigger sequence and matching the corresponding drive.

2.the impact of wide temperature on different touch screens

1) Capacitive screen

The working principle of a Capacitive Touch Screen is to use a touch sensor to induce a voltage on the conductor on the screen, thereby generating a relative current, and measuring the touch point by distance. In the case of low temperature, the skin surface of the hands has low moisture content, and the dry and cold skin has poor conductivity. At the same time, when the ambient temperature is low, the performance of the sensor will also be affected, and the industrial touch display cannot recognize the touch position well, causing the touch screen to malfunction. The operating temperature of the touch screen is usually between -5°C and +60°C, especially in winter, the northern area is more affected.

2) Resistive touch screen

The resistive touch screen is less affected. On the one hand, because of the different processes used, the micro-circuit on the touch screen is connected to work, which is weakly affected by the temperature. On the other hand, the technological level of the resistive screen is relatively mature, and the materials used are all able to withstand the test and continue to be used. The temperature of the resistive screen is required to be between -20℃~65℃, which can meet most of the use environments.

3) Infrared touch screen

The accuracy of the infrared touch screen is completely free from current, voltage and static electricity interference, and is suitable for various environmental conditions with light pollution. However, the infrared touch screen is limited because of its single sensor, easy to be damaged and aging, and the touch interface cannot withstand pollution, destructiveness, and complicated maintenance. When the temperature is extremely low, the static electricity generated during the use of industrial displays tends to attract dust, thereby affecting the use. Suitable for use in the aerospace field.

4) Surface acoustic wave screen

It shows that the sonic touch screen has extremely high definition, the light transmittance can reach 92%, the anti-scratch, abrasion performance is also the best, the response is sensitive, and the accuracy is completely unaffected by environmental factors such as temperature and humidity. In contrast, the cost of construction and maintenance are also high. Surface acoustic wave screens need frequent maintenance. If dust, oil stains or even liquids are contaminated on the surface of the touch screen, the wave guide groove on the surface of the touch screen will be blocked, causing the sound wave to not be emitted normally or causing the waveform to change and the controller cannot recognize it correctly. Therefore, strict attention must be paid to environmental hygiene, and the surface of the touch screen must be wiped frequently to keep it smooth and clean, and a complete and thorough erasure must be performed regularly. If the surface of the sonic screen is condensed or oily in winter, it will be quite troublesome to clean.

3. Industrial-grade display that meets wide temperature requirements

The front panel is designed with aluminum wire drawing process, and the arc edge is harmonious; at the same time, the touch mode supports five-wire resistive and capacitive, with a wide temperature LED backlight LCD screen. The wide temperature performance of the whole machine has been tested by long-term controllable high and low temperature standards. . In addition, it pays more attention to its reliability, environmental adaptability, real-time, scalability, EMC compatibility and other performances in the materials of the complete machine.

In terms of configuration, the self-developed RJ45 driver board is used to support HDMI input, DVI input, VGA input interface and other anti-dropping DC thread wide-voltage power supply interfaces, which can meet the needs of the scene. At the same time, it also supports buckle embedded, horizontal shutter, wall-mounted, desktop and other installation methods to unlock more application scenarios.

The company also provides Industrial Tablet Computers and mini computers, please feel free to contact us if necessary